Proven work over 20 years’ construction experience with multinational companies and multi races peoples included 8 year as manager for feed, planning, calculating, execution and control, commissioning, handover and delivered various unique projects based on the scope, schedule, budget within the commitment to the client satisfaction value in oil and gas petrochemical, infrastructures, buildings and marine facilities

Mastering in Project Management Professional with strong knowledge with Project Finance Turn Over circulation. Aware with business continuity in sustainability aspects of commercials. Team work player and able to handling collaborative team with leading leadership character, focus and attention in details right first time.

CERTIFICATION

• PMP® - Project Management Institute

• Project Management Professional – PPM Management

- FINON Executive Financial Statement

• FIDIC Condition and Contract - FIDIC

• Business impact analysis level 2 – Michelin

• Project system turn over – SRI

• Step back manager level II - BAM

• CSWIP 3.1 welding Insp 2 – TWI CL

EDUCATION

Bachelor civil engineer Jayabaya University – Jakarta, graduated 2005

BUSSINESS LEADERSHIP STRATEGIES

KEY RELATIONSHIP

o Project Board Members, Development Director, Finance Director

o Internal key stakeholders – Project Director, Construction Manager, Line Managers

o External stakeholders – Clients managers, contractors, vendors, suppliers, local communities, authorities and permits

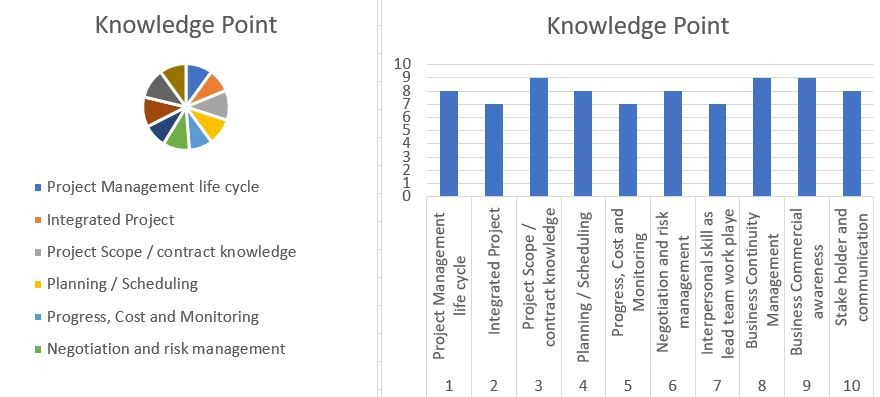

SKILL EXPERTISE

MAJOR PROJECT ACCOMPLISMENT

Petrochemical

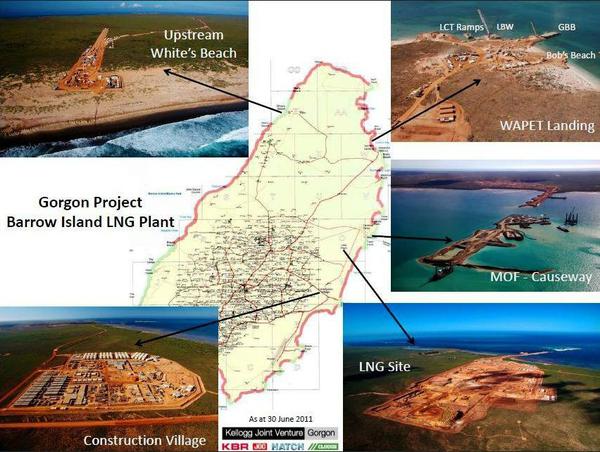

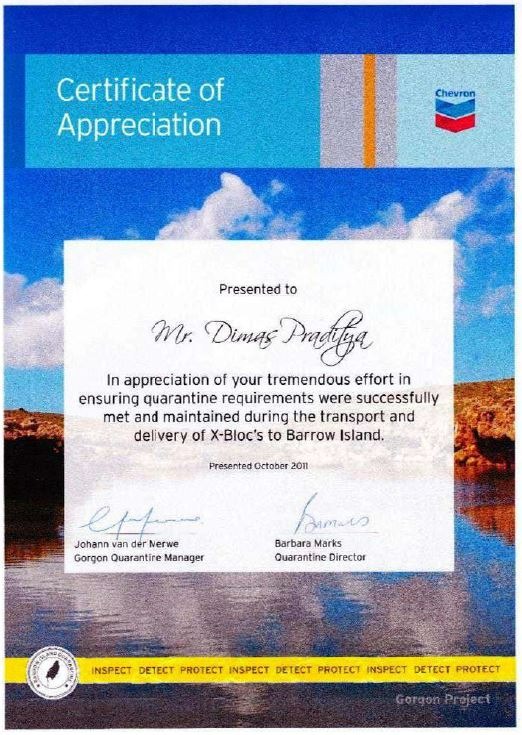

Oil and Gas

Hotel, Office, Apartment and Warehouse

Dredging and Reclamation

Pluit City artificial island at Jakarta bay

Marine Infrastructure and Jetty Facility

Concrete loading quays jetty, Pipe rack jetty and marine facility (Platforms, Fenders, Bollards, Guard rails, Dolphins, Sea wall protection, rock revetment, E&I system, etc)

SOFTWARE

o MS Office, MS Project, PPT, Visio, AutoCAD, Navisworks 3D,

o CMMS, Maximo, SAP, ERP Oracle, BIB integrated

Commissioning Manager for CPPE – CHINA PETROLEUM PIPELINE ENGINERING

Refinery Development Master Plan for Pertamina RU V - Lawe lawe packages / Onshore and Offshore Project

August 2021 – Present

Managed the Contractor Commissioning department for the smooth transition from construction to normal operation of the refinery plant